We are Shaoyi

Industry-leading manufacturer of automotive metal parts

- We offer CAE analysis services, 24-hour rapid quoting, and possess fifteen years of experience in manufacturing metal components. With a seasoned team of engineers, we provide feasibility analysis reports to assist clients in early-stage development. Our commitment to delivering high-quality, professional services in automotive component manufacturing contributes to the advancement of the automotive industry

Focus on the Automotive ndustry

Our processes serve the automotive industry, providing them with superior solutions. Whether it is precision parts processing, advanced material research and development, or efficient production process optimization, we are committed to providing the highest quality process support to automobile manufacturers. Through continuous innovation and technological upgrading, we ensure that our automotive industry customers receive products that meet the highest standards, allowing them to stand out in a highly competitive market.

Our processes serve the automotive industry, providing them with superior solutions.

Our processes serve the automotive industry, providing them with superior solutions.

1.Production management MES system enables enterprises to achieve lean production.

2.The customer MES system meets their rapid delivery needs.

3.The quality management MES system allows for immediate quality feedback and rapid response.

4.The MES system for production progress achieves controllable factory processes.

5.Real time management of MES systems enables enterprises to achieve transparent management.

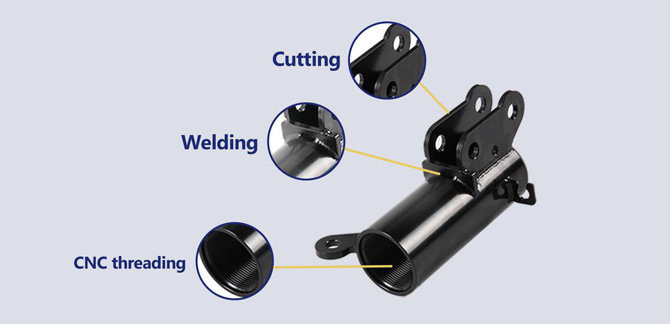

- Various automotive accessories

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery