| zhangasn | Manufacturing Processes and Materials | Manufacturing Processes and Materials | |

|---|---|---|---|

|

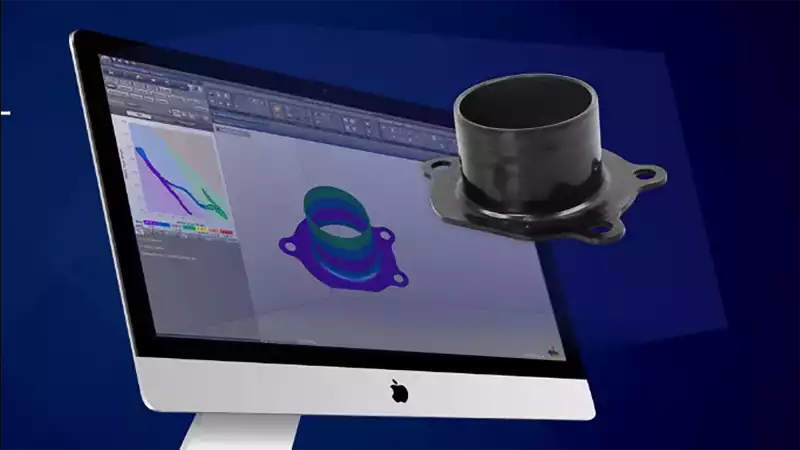

CNC Machining Materials

|

Metals

Aluminum Brass Copper Stainless Steel Steel Alloy Steel Mild Low Carbon Titanium |

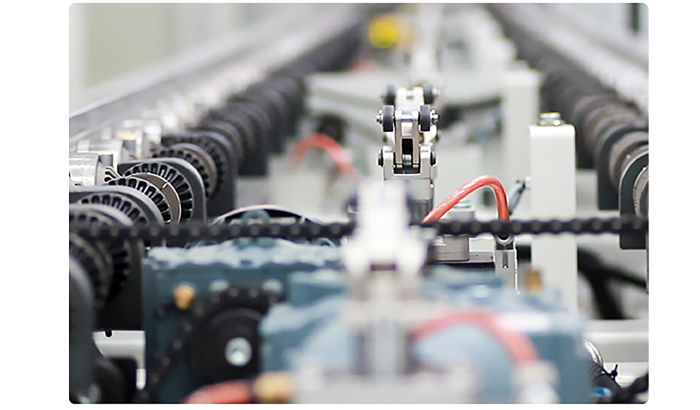

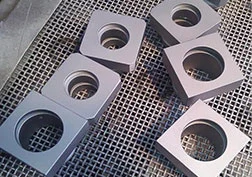

Pipe Processing

|

steel tube

Carbon tube Alloy pipe stainless steel pipe Aluminum alloy plate 6061 Aluminum 6082 Aluminum 7075 Aluminum |

|

Cold Extrusion

|

steel

Carbon steel Alloy steel stainless steel Aluminum 6061 Aluminum 6082 Aluminum 7075 Aluminum |

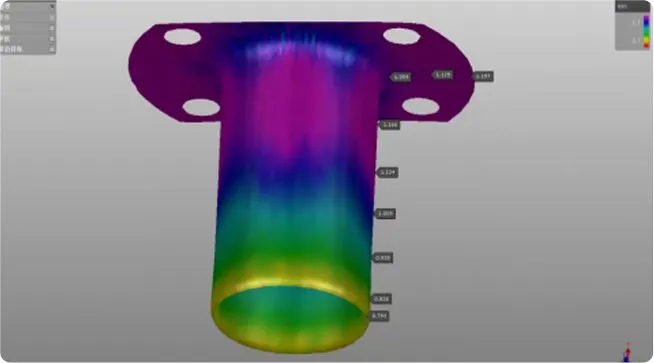

Here is our production requirement for ourselves: 1.Strictly adhere to the stipulated production deadlines of each batch. 2.Respond quickly to changes in drawings. Details are constantly being improved. 3.Adhere to very high surface requirements when it comes to key engine parts. 4.Adhere to the requirements for electrical conductivity. 5.Respond quickly to designer comments.

| Processing Capabilities | Processing Capabilities | ||

|---|---|---|---|

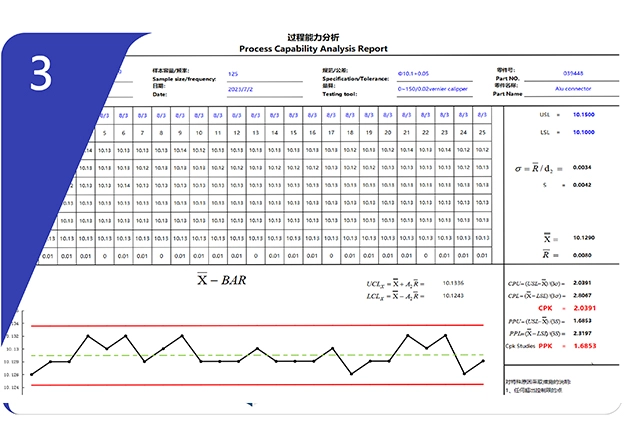

| Maximum part Size | 300mm*200mm*200mm | Perpendicularity | 0.05mm |

| Minimum Part Size | 8mm*6mm*4mm | Oxidize | Film thickness 8-15um |

| Tolerances | 0.02mm | Heat treatment | Hardness 28°-65° |

| Concentricity | 0.05mm | Electrophoresis | Film thickness 15-35um, salt spray test 720h without red rust |

| Remark |

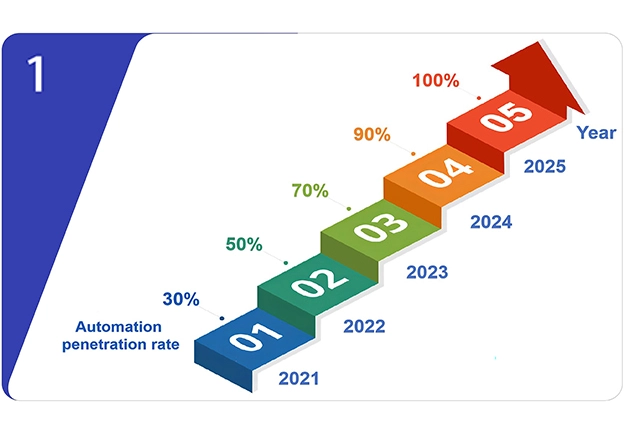

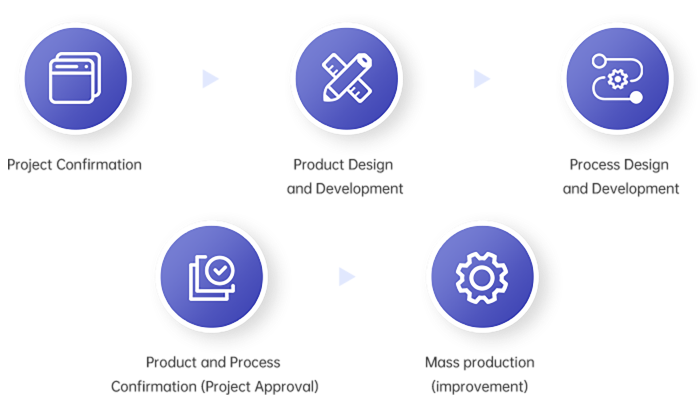

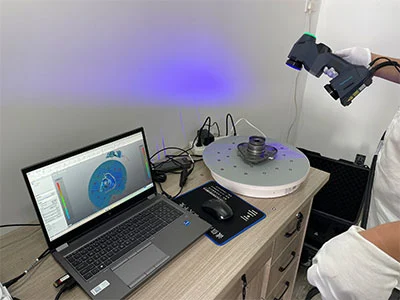

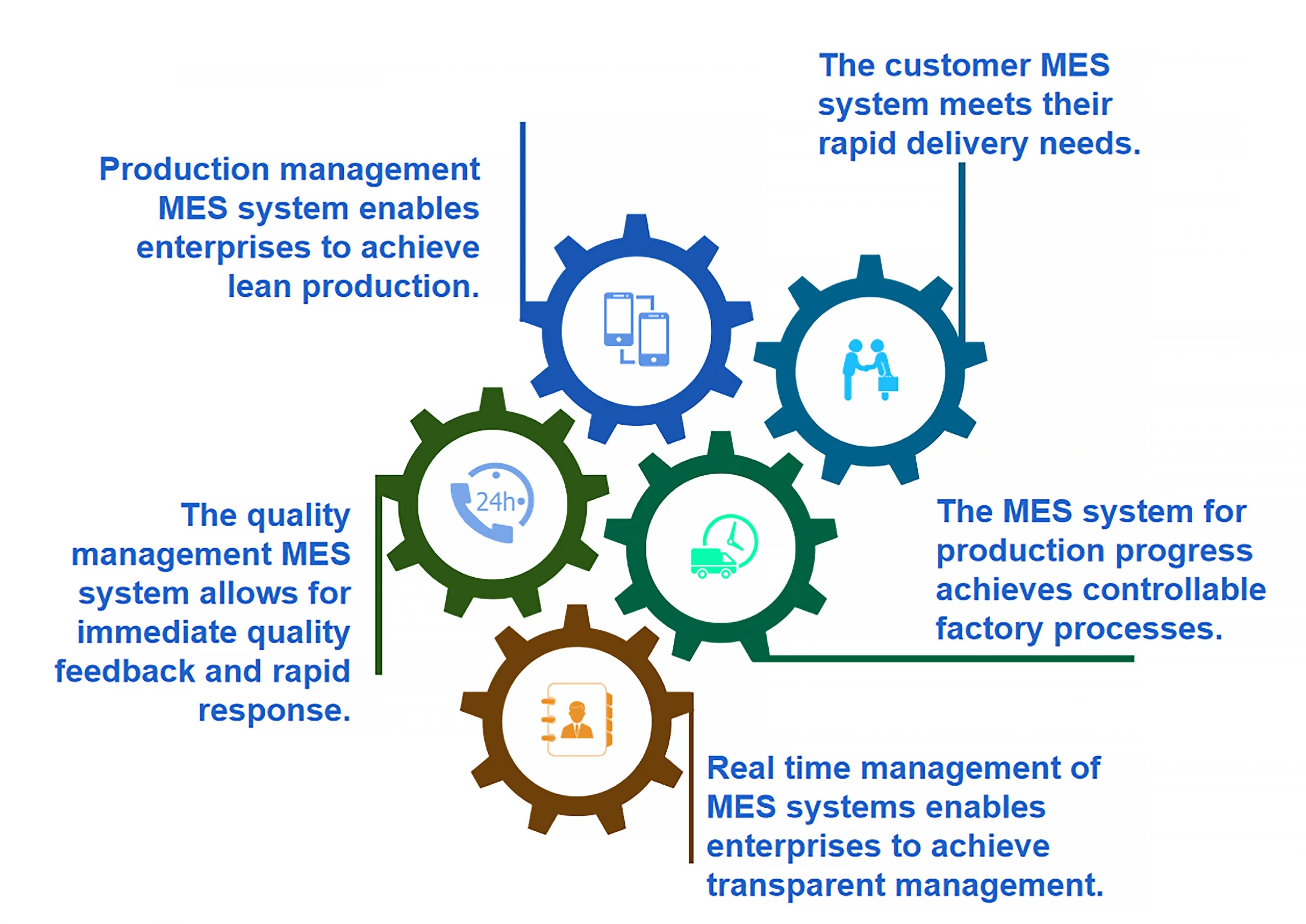

1.Production management MES system enables enterprises to achieve lean production.

2.The customer MES system meets their rapid delivery needs.

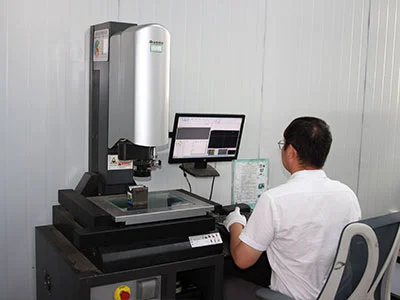

3.The quality management MES system allows for immediate quality feedback and rapid response.

4.The MES system for production progress achieves controllable factory processes.

5.Real time management of MES systems enables enterprises to achieve transparent management.

After receiving detailed information(your 2D/3D drawings), we will quote you within 12 hours. If the quote is delayed by some reasons, we will notify you.

- Various automotive accessories

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery