Phosphating Process: Revolutionizing Automotive Metal at Shao Yi

Introduction:

Phosphating process:In the intricate world of automotive metal component manufacturing, where precision, durability, and corrosion resistance are paramount, Shao Yi emerges as a pioneer, steering the industry towards innovative solutions. At the heart of our manufacturing excellence lies a crucial step—phosphating. In this comprehensive blog, we delve into the intricacies of the phosphating process, exploring how Shao Yi’s commitment to quality and innovation is shaping the future of automotive metal components.

1. Understanding Phosphating:

Definition and Purpose:

Phosphating is a surface treatment process that involves the formation of a phosphate coating on metal surfaces. This coating serves as a protective layer, enhancing the metal’s corrosion resistance, promoting paint adhesion, and providing a foundation for improved performance and longevity.

Types of Phosphating:

Shao Yi employs various types of phosphating processes, including zinc phosphating, manganese phosphating, and iron phosphating. Each type offers specific advantages and is selected based on the intended application and performance requirements of the metal component.

2. The Phosphating Process at Shao Yi:

Pre-Treatment and Cleaning:

Before the phosphating process begins, metal components undergo meticulous pre-treatment and cleaning. This step removes contaminants, oils, and residues, ensuring a pristine surface for the subsequent phosphating treatment.

Activation:

The metal surface is activated to facilitate the bonding of the phosphate coating. Shao Yi employs advanced activation techniques, optimizing the surface for maximum coating adhesion and uniformity.

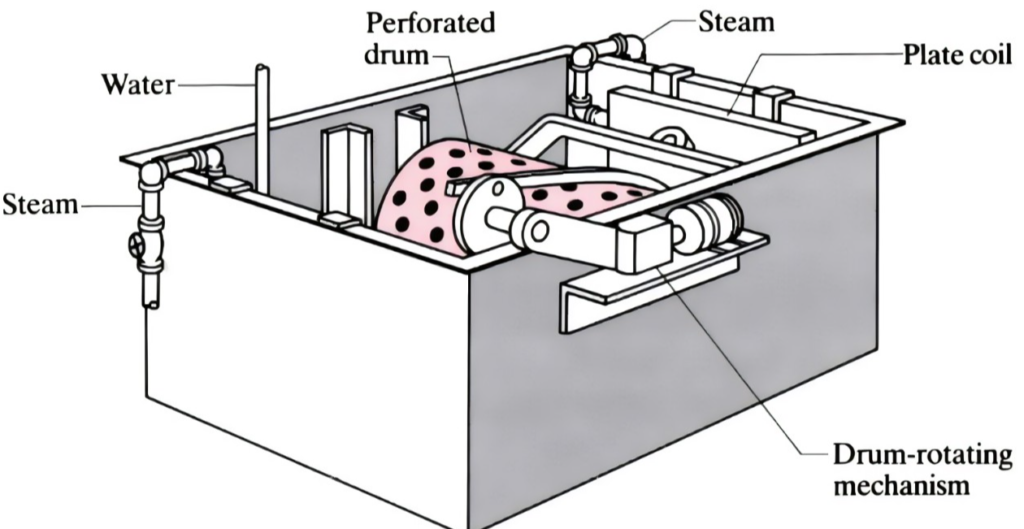

Phosphating Bath Immersion:

The heart of the process involves immersing the metal components into a phosphating bath. Shao Yi utilizes carefully formulated chemical solutions to initiate the conversion of the metal surface into a phosphate coating. This step is a delicate dance of chemistry and precision, and our experts ensure that the conditions are optimal for superior results.

Rinsing and Drying:

Post-phosphating, thorough rinsing is crucial to remove any residual chemicals. Shao Yi incorporates advanced rinsing techniques, followed by precision drying, ensuring that the components emerge with a flawless, uniform phosphate coating.

3. Advantages of Phosphating at Shao Yi:

Enhanced Corrosion Resistance:

The primary advantage of phosphating is the remarkable enhancement of corrosion resistance. Shao Yi’s phosphated components exhibit superior protection against environmental factors, ensuring prolonged lifespan and reliability.

Improved Paint Adhesion:

The phosphate coating serves as an ideal substrate for paint adhesion. Components treated through Shao Yi’s phosphating process provide a robust foundation for paint, leading to enhanced aesthetics and prolonged paint durability.

Surface Lubricity:

Certain phosphating formulations contribute to the development of a microcrystalline structure on the metal surface, imparting surface lubricity. This property is particularly valuable in automotive applications where reduced friction is critical.

Application Versatility:

Shao Yi’s utilization of different phosphating types allows for application versatility. From chassis components to intricate parts, the phosphating process is tailored to meet the specific demands of diverse automotive metal components.

4. Quality Assurance and Innovation:

Advanced Testing and Inspection:

Shao Yi places a premium on quality assurance. Rigorous testing and inspection procedures ensure that each phosphated component meets or exceeds industry standards. Advanced technologies are employed to assess coating thickness, adhesion strength, and overall quality.

Continuous Research and Development:

The phosphating process at Shao Yi is not static; it evolves through continuous research and development. Our experts explore innovative formulations, application techniques, and process optimizations, ensuring that we stay ahead in the ever-evolving landscape of metal component surface treatments.

5. Environmental Considerations:

Eco-Friendly Practices:

Shao Yi is committed to environmentally friendly practices in its phosphating processes. We actively explore formulations and techniques that minimize environmental impact, aligning with global sustainability goals.

Waste Management:

Effluent treatment and waste management are integral components of Shao Yi’s phosphating operations. Our systems are designed to minimize waste generation and adhere to stringent environmental regulations.

6. Industry Applications and Future Trends:

Automotive Components:

Shao Yi’s phosphated components find application in various automotive parts, including chassis components, fasteners, brackets, and more. The enhanced corrosion resistance and paint adhesion properties make them indispensable in the demanding automotive environment.

Advancements in Formulations:

The future of phosphating holds exciting prospects, with ongoing research focusing on advanced formulations that provide even greater durability, enhanced lubricity, and tailored solutions for specific automotive applications.

Integration with Digital Technologies:

Shao Yi is at the forefront of integrating digital technologies with the phosphating process. Real-time monitoring, data analytics, and predictive maintenance contribute to the efficiency and quality of phosphated components.

Conclusion:

As we navigate the complex landscape of automotive metal component manufacturing, Shao Yi’s dedication to excellence shines through its innovative phosphating process. The fusion of precision, technology, and environmental consciousness propels us forward, ensuring that the components we produce are not only robust and reliable but also aligned with the evolving demands of the automotive industry. In the realm of surface treatments, phosphating stands as a testament to Shao Yi’s commitment to quality and innovation—a crucial step towards a future where automotive components set new standards in durability, performance, and environmental responsibility.

***FAQs on Shao Yi’s Phosphating Process: Revolutionizing Automotive Metal Components***

1. What is phosphating, and why is it important in automotive metal component manufacturing?

Phosphating is a surface treatment process that involves the formation of a phosphate coating on metal surfaces. It is crucial in automotive manufacturing for enhancing corrosion resistance, promoting paint adhesion, and providing a foundation for improved performance and longevity of metal components.

2. What types of phosphating processes does Shao Yi employ, and how are they chosen for specific applications?

Shao Yi employs various types of phosphating processes, including zinc phosphating, manganese phosphating, and iron phosphating. The selection is based on the intended application and performance requirements of the metal component.

3. Can you explain the steps involved in Shao Yi’s phosphating process?

The phosphating process at Shao Yi involves pre-treatment and cleaning, activation of the metal surface, immersion in a phosphating bath, and post-phosphating rinsing and drying. Each step is meticulously executed to ensure a flawless and uniform phosphate coating.

4. What advancements can we expect in the future of phosphating at Shao Yi?

The future of phosphating holds exciting prospects at Shao Yi, with ongoing research focusing on advanced formulations for greater durability, enhanced lubricity, and tailored solutions for specific automotive applications. Integration with digital technologies for real-time monitoring and predictive maintenance is also a key focus.