Quality Assurance in Auto Parts: How IATF16949 Certification Sets Us Apart

Introduction

In the world of automotive manufacturing, where precision, safety, and reliability are paramount, the quality of auto parts cannot be compromised. Every component, regardless of its size, plays a critical role in the overall performance and safety of a vehicle. To ensure the highest quality standards for automotive components, the International Automotive Task Force (IATF) introduced the IATF16949 certification. In this comprehensive blog post, we will delve deeply into the significance of IATF16949 certification and how it distinguishes our company , showcasing our unwavering commitment to quality.

Understanding IATF16949 Certification

Before we explore the importance of IATF16949 certification, let’s first understand what it entails. IATF16949 is a globally recognized quality management system standard specifically designed for the automotive industry. It builds upon the ISO 9001 standard but adds additional automotive-specific requirements. IATF16949 outlines the requirements for a quality management system that helps organizations consistently meet customer and regulatory requirements in the automotive sector.

The Significance of IATF16949 Certification

IATF16949 certification is of paramount importance in the automotive industry for several compelling reasons:

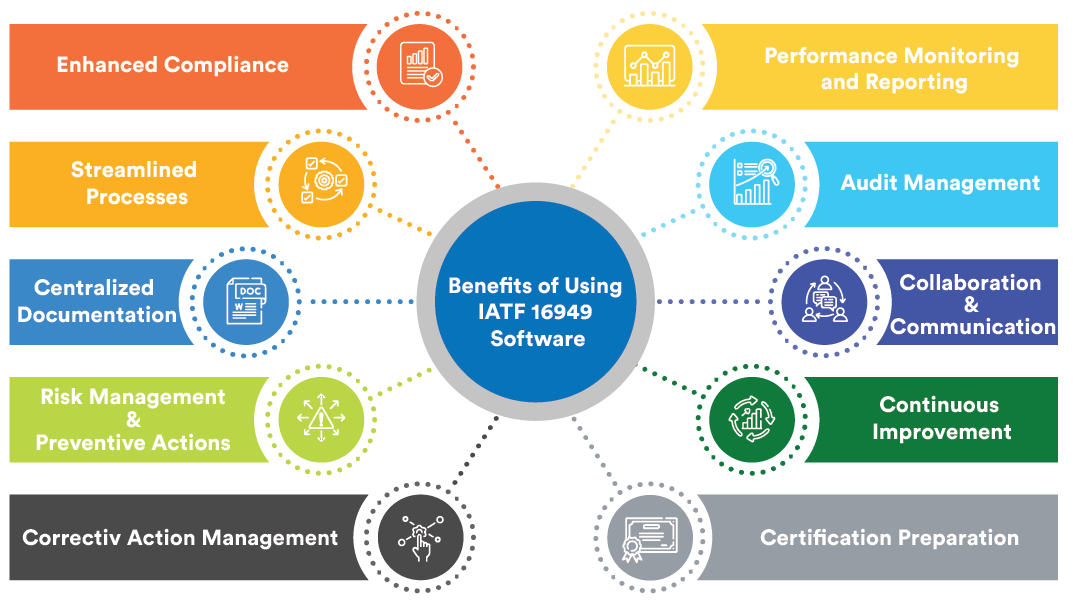

1.Stringent Quality Standards: IATF16949 certification sets rigorous quality standards that automotive component manufacturers must adhere to. It encompasses a wide range of criteria, from design and production to customer satisfaction and continuous improvement. This ensures that every step of the manufacturing process is optimized for quality.

2.Global Recognition: IATF16949 is recognized and accepted worldwide. This means that certified companies can supply their products to automotive manufacturers around the globe, opening up international markets and opportunities. It provides a universal language for quality assurance in the automotive industry.

3.Reduced Defects: The implementation of IATF16949 processes reduces defects and ensures that products consistently meet or exceed customer expectations. This results in fewer recalls and warranty claims for automotive manufacturers, saving them both money and reputation.

4.Enhanced Efficiency: IATF16949 emphasizes process efficiency and waste reduction. This not only leads to cost savings but also promotes environmentally friendly manufacturing practices. It aligns quality with sustainability, a growing concern in the automotive sector.

5.Customer Confidence: IATF16949 certification instills confidence in customers and partners. It demonstrates a commitment to delivering high-quality products and consistently improving processes. It signifies that a company is dedicated to maintaining the highest standards of quality.

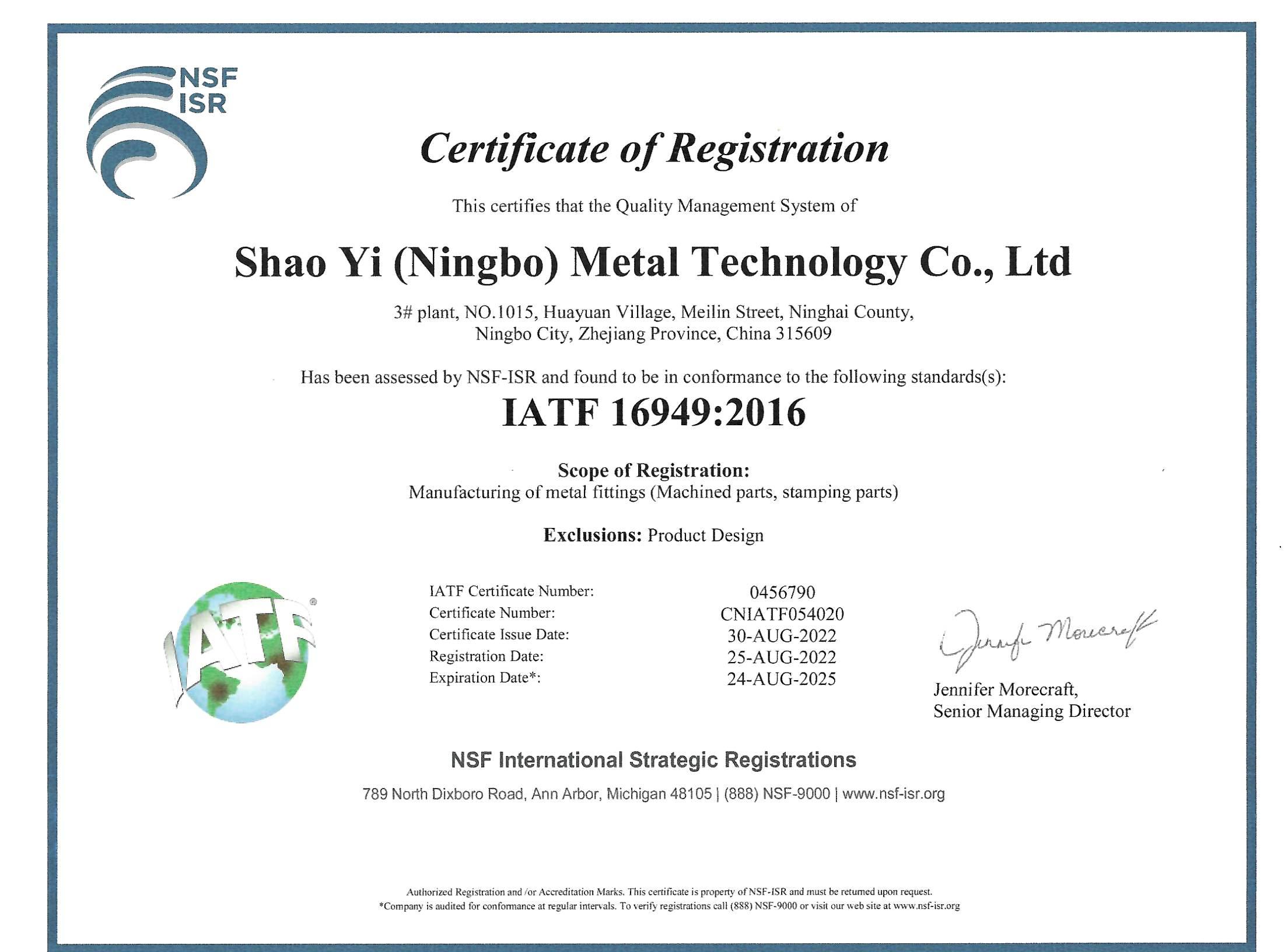

SHAOYI’s Commitment to Quality through IATF16949 Certification

At SHAOYI, we take quality seriously, and our IATF16949 certification reflects this commitment. Here’s how we stand out:

1.Adherence to Standards: We rigorously adhere to the IATF16949 standards in all aspects of our operations, from design and development to production and delivery. Every member of our team is well-versed in the requirements and works diligently to ensure compliance.

2.Continuous Improvement: Our commitment to quality extends beyond certification. We have embraced a culture of continuous improvement, where every employee is encouraged to seek ways to enhance our processes and products. We view every challenge as an opportunity for growth and refinement.

3.Skilled Workforce: Our team is comprised of highly skilled professionals who are not only experts in their respective fields but also committed to upholding the principles of IATF16949. They ensure that every product leaving our facility meets the highest quality standards.

4.Cutting-Edge Technology: We understand that precision and consistency are at the core of quality. To achieve this, we invest in state-of-the-art technology and equipment, ensuring that our manufacturing processes are on the leading edge of industry standards.

5.Customer Focus: We recognize that each customer may have unique requirements. We work closely with our customers to understand their specific needs and provide customized solutions that meet or exceed their expectations. Our commitment to customer satisfaction is unwavering.

The Journey of IATF16949 Certification

Achieving and maintaining IATF16949 certification is no small feat. It’s a rigorous process that involves careful planning, implementation, and continuous monitoring. Here’s an overview of what it entails:

1. Gap Analysis: The journey typically begins with a gap analysis. This involves a thorough review of our existing quality management system to identify areas where it aligns with IATF16949 and areas where improvements or changes are necessary.

2. Training: We ensure that all employees receive appropriate training on IATF16949 requirements and the importance of quality management. This training extends to all levels of our organization, from the shop floor to top management.

3. Process Improvement: With a focus on continuous improvement, we systematically review and enhance our manufacturing processes. This includes everything from design and development to production, testing, and delivery. Each process is analyzed for efficiency, effectiveness, and compliance with IATF16949 standards.

4. Documentation: Thorough documentation is a cornerstone of IATF16949 certification. We meticulously document our processes, procedures, and quality control measures. This documentation not only demonstrates compliance but also serves as a valuable resource for ongoing improvement efforts.

5. Internal Audits: We conduct regular internal audits to ensure that our quality management system is functioning as intended. These audits help identify areas for improvement and allow us to take corrective actions when necessary.

6. External Certification Audit: Once we are confident in our adherence to IATF16949 standards, an external certification body conducts a rigorous audit. This audit evaluates our quality management system against the IATF16949 requirements. Achieving certification is a testament to our commitment to quality.

Conclusion

In the competitive world of automotive manufacturing, quality is non-negotiable. IATF16949 certification is the gold standard for ensuring the highest quality standards for automotive components. Our company’s commitment to achieving and maintaining this certification sets us apart from the rest. It signifies our dedication to delivering products that not only meet but exceed industry standards, giving our customers the confidence they need in their supply chain.

With IATF16949 as our guiding principle, we continue to drive innovation and excellence in the automotive component industry. Our goal is not just to provide auto parts but also to provide peace of mind to our customers, knowing that every component we deliver is of the highest quality and adheres to the most stringent standards.

In closing, the pursuit of excellence through IATF16949 certification is at the core of our commitment to delivering exceptional quality in the automotive industry. SHAOYI firmly believes that every detail matters, and precision is our promise. As you’ve explored the significance of IATF16949 certification and our unwavering dedication to it, we invite you to take the next step with us. Whether you’re an automotive manufacturer seeking reliable partners or simply share our passion for uncompromising quality, we encourage you to Contact Us today. Let’s work together to elevate the standards of the automotive industry and ensure that every vehicle on the road is a testament to precision and safety.