Revolutionizing Automotive Manufacturing: CNC Machine Tools in Assembly Plants

Introduction:

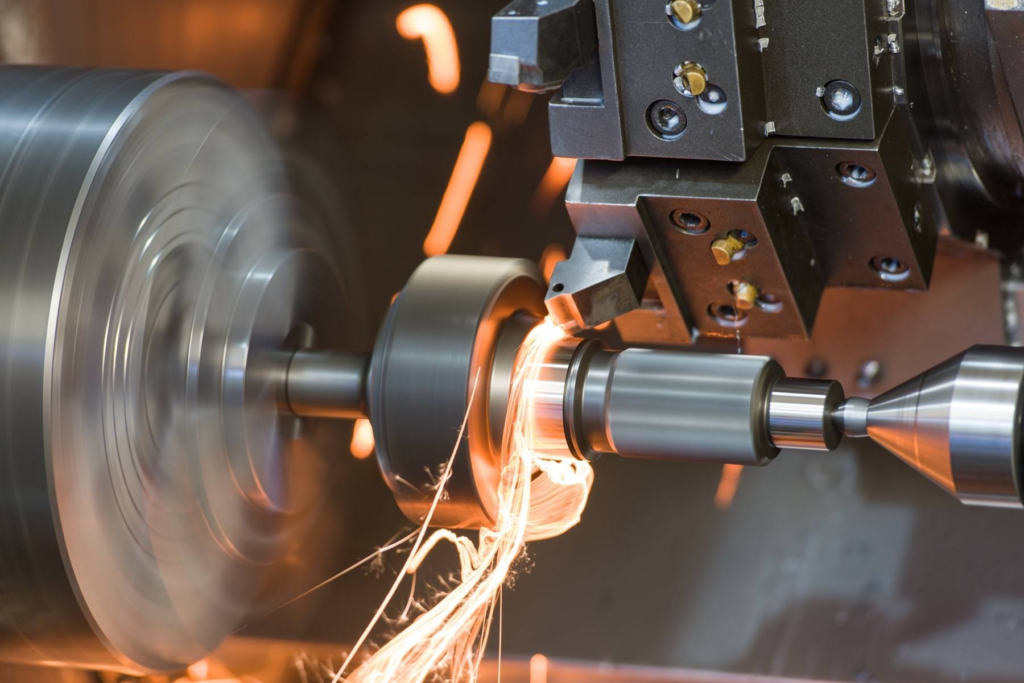

In the dynamic landscape of automotive manufacturing, precision, efficiency, and reliability are paramount. At Shaoyi Company, we are at the forefront of innovation. Harnessing the power of CNC machine tools to transform automotive assembly plants. In this blog, we delve into the application and case studies of CNC machine tools in automotive assembly plants. Showcasing how Shaoyi Company’s expertise and advantages contribute to driving efficiency and excellence in the automotive industry.

The Role of CNC Machine Tools in Automotive Assembly Plants:

CNC machine tools have revolutionized the automotive manufacturing process, offering unmatched precision, flexibility, and productivity. In automotive assembly plants, CNC machine tools play a critical. Role in fabricating components, machining parts, and assembling vehicles with exceptional accuracy and efficiency. From engine blocks and transmission components to chassis elements and body panels. CNC machine tools enable automotive manufacturers to meet the demands of modern vehicle production with precision and reliability.

Advantages of Shaoyi Company’s CNC Machining Solutions:

1.State-of-the-Art Facilities:

Shaoyi Company operates advanced manufacturing facilities equipped with the latest CNC machine tools and cutting-edge technologies.These facilities ensure the deliver of precision- engineered with unparalleled efficiency and consistency, meeting the stringent requirements of automotive assembly plants.

2.Expertise and Experience:

With years of experience in CNC machining, our team of skilled engineers and technicians possesses deep expertise in programming, tooling optimization, and process automation. Their proficiency allows us to tackle complex machining challenges and deliver cost-effective solutions tailored to the unique needs of automotive assembly plants.

3.Quality Assurance:

Quality is ingrained in our processes at Shaoyi Company. We adhere to rigorous quality control measures throughout the manufacturing process, ensuring that every component meets the highest standards of accuracy and performance. Our commitment to quality assurance minimizes rework and waste, contributing to overall cost optimization and customer satisfaction.

4.Efficient Production Processes:

Leveraging CNC machining, Shaoyi Company optimizes production processes to maximize efficiency and minimize lead times. From rapid prototyping to high-volume production runs, our streamlined workflows. Agile manufacturing approach enable us to meet the demanding production schedules of automotive assembly plants without compromising quality or reliability.

Case Studies:

1.Engine Block Machining:

Shaoyi Company collaborated with a leading automotive assembly plant to optimize the machining process for engine blocks. By leveraging advanced CNC machine tools and innovative tooling solutions. We achieved significant reductions in cycle times and improved dimensional accuracy. Resulting in enhanced productivity and cost savings for the assembly plant.

2.Transmission Component Production:

In another case study, Shaoyi Company partnered with an automotive OEM to streamline the production of transmission components. Through the implementation of state-of-the-art CNC machining techniques and stringent quality control measures. We delivered precision-engineered components that met the stringent performance requirements of the assembly plant. Contributing to the overall reliability and performance of the vehicles produced.

Conclusion:

In conclusion, CNC machine tools play a vital role in driving efficiency and excellence in automotive assembly plants. At Shaoyi Company, our commitment to innovation, expertise. And quality assurance enables us to deliver cutting-edge CNC machining solutions that meet the demanding needs of automotive manufacturers. Through our state-of-the-art facilities, skilled workforce, and customer-centric approach. We continue to push the boundaries of precision machining excellence, driving success in the automotive industry and beyond.