Revolutionizing Manufacturing: Digitalized Stamping for Superior Components

In the era of Industry 4.0, the landscape of manufacturing is undergoing a profound transformation, and at Shaoyi, we stand at the forefront of this revolution. In this blog post, we explore the paradigm shift brought about by the digitalization of stamping processes, unveiling how it is reshaping the landscape of component manufacturing.

The Essence of Digitalized Stamping:

Digitalized stamping represents a departure from traditional manufacturing methods, integrating cutting-edge digital technologies into the heart of the stamping process. This evolution is driven by the need for enhanced efficiency, precision, and adaptability in response to the dynamic demands of the modern industrial landscape.

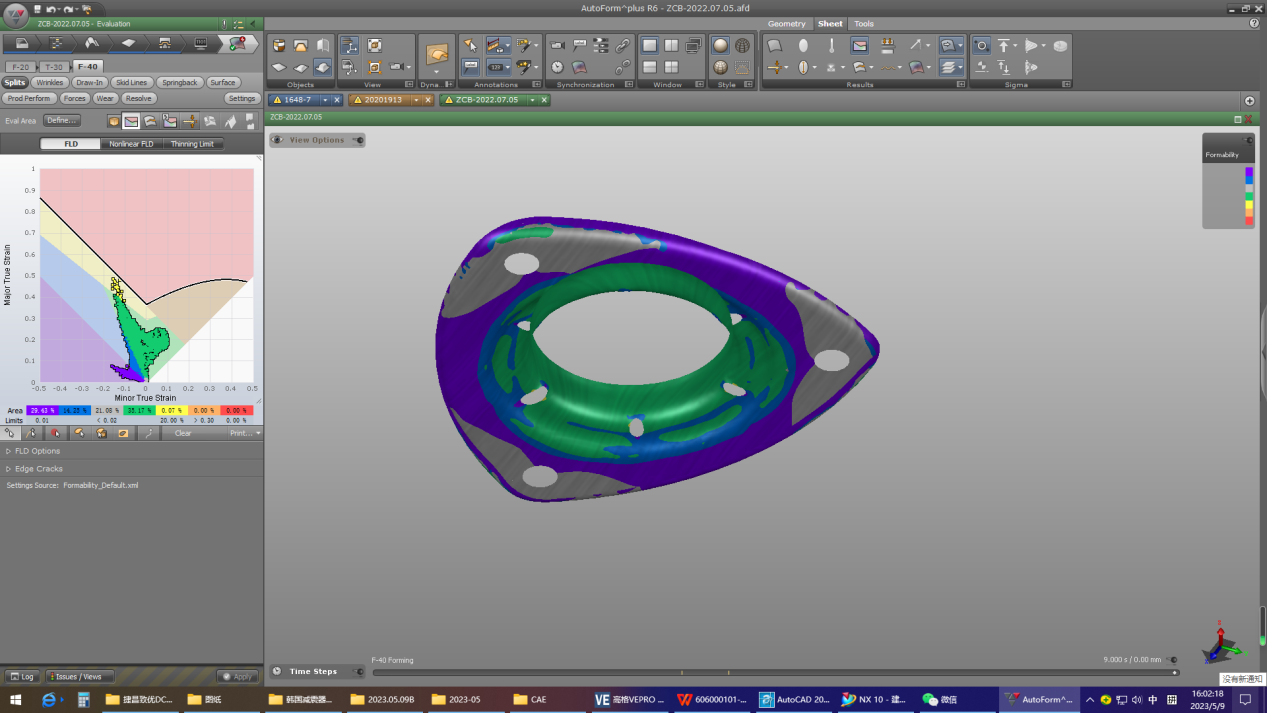

Precision Redefined:

Digitalized stamping elevates precision to new heights. Through the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, our engineers can create intricate designs with unparalleled accuracy. The result is a level of precision that meets and exceeds the stringent requirements of diverse industries.

Efficiency Unleashed:

The marriage of digital technologies with stamping processes unlocks unprecedented levels of efficiency. Automation plays a pivotal role, streamlining production workflows and reducing manual intervention. This not only accelerates the manufacturing timeline but also minimizes the likelihood of errors, ensuring a seamless and efficient production cycle.

Adaptability and Customization:

In the realm of digitalized stamping, adaptability is a key advantage. The flexibility afforded by digital technologies allows for swift adjustments to design specifications and manufacturing parameters. This adaptability is particularly crucial in an era where customization is king, enabling us to cater to the unique needs of every client and project.

Real-Time Monitoring and Quality Assurance:

Digitalization introduces real-time monitoring capabilities, providing insights into every facet of the stamping process. From material flow to machine performance, these data-driven insights empower us to make informed decisions on the fly, enhancing quality control and reducing the likelihood of defects.

Environmental Sustainability:

Beyond efficiency and precision, digitalized stamping aligns with our commitment to environmental sustainability. The optimization of material usage and the reduction of waste contribute to eco-friendly manufacturing practices. As we embrace digital technologies, we are not only enhancing our operational efficiency but also minimizing our ecological footprint.

Empowering Innovation:

Digitalized stamping is a catalyst for innovation. It opens the door to new design possibilities, enabling the creation of components that were once deemed challenging or impractical. This empowerment of innovation is a testament to the transformative potential of digital technologies in the manufacturing landscape.

The Future of Manufacturing:

As we navigate the digitalized future of stamping processes, the possibilities are limitless. The ongoing integration of artificial intelligence, machine learning, and the Internet of Things (IoT) promises to further revolutionize the way we approach component manufacturing. The future holds a landscape where digitalized stamping is not just a tool but an integral part of the manufacturing ecosystem.

In conclusion, at Shaoyi, our embrace of digitalized stamping signifies a commitment to pushing the boundaries of what is possible in component manufacturing. Through precision, efficiency, adaptability, real-time monitoring, sustainability, and innovation, we are shaping the future of manufacturing in a digital age. Join us on this transformative journey where every stamped component reflects the epitome of digital excellence.