Shaoyi’s Excellence in Metal Material Applications: Exploring the World of Various Metals

Metallic materials have always been a cornerstone of the manufacturing sector, with widespread applications in areas like automotive, aerospace, construction and electronics. Metals come with their unique properties and uses, and Shaoyi has always spearheaded innovations and applications in the field of metal materials. In this blog, we delve deeper into the characteristics and applications of different metals, showcasing Shaoyi’s prowess in this domain.

Metallic materials have always been a cornerstone of the manufacturing sector, with widespread applications in areas like automotive, aerospace, construction and electronics. Metals come with their unique properties and uses, and Shaoyi has always spearheaded innovations and applications in the field of metal materials. In this blog, we delve deeper into the characteristics and applications of different metals, showcasing Shaoyi’s prowess in this domain.

Characteristics of Different Metal Materials

Steel: Steel is a strong and durable metal with excellent compressive and tensile strength. It is commonly used in construction, bridges and automobile manufacturing. Different types of steel can be adjusted in composition to achieve different properties, such as stainless steel for corrosion resistance.

Aluminum: Aluminum is a lightweight metal with good thermal and electrical conductivity. It is widely used in the aerospace, automotive, electronics and packaging industries. The advantages of aluminum are its light weight and recyclability.

Copper: Copper is a good conductor of electricity and is therefore widely used in electronics and electrical engineering. It also has good thermal conductivity and is used in the manufacture of radiators and pipes.

Magnesium: Magnesium is a lightweight metal used extensively in aerospace and automotive manufacturing to reduce weight and improve fuel efficiency. However, magnesium is susceptible to corrosion and requires special treatment.

Titanium: Titanium is a high-strength, low-density metal with excellent corrosion resistance. It is commonly used in high-end applications in the aerospace, medical and chemical sectors.

Applications for Different Metals

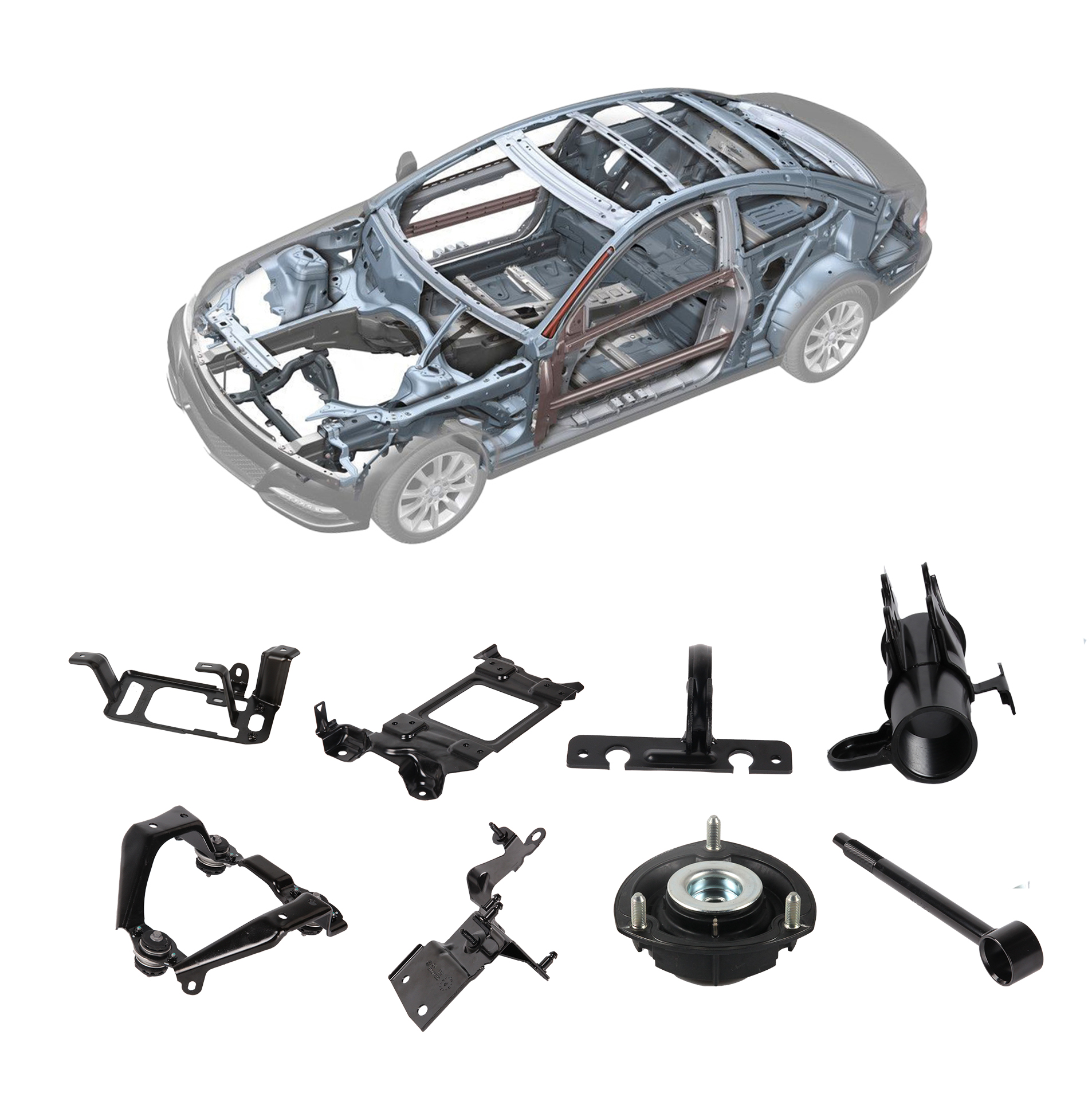

Automotive: Steel and aluminum are the most commonly used metals in automotive manufacturing. Steel is used for the body and chassis, while aluminum is used for lightweight components such as engines and wheels.

Aerospace: Lightweight metals such as aluminum, magnesium and titanium have a wide range of applications in aerospace, helping to reduce the weight of planes and rockets and improve fuel efficiency.

Electronics and Electrical Engineering: Copper is a key material in electronics and electrical engineering, used in the manufacture of wires, cables and circuit boards. Aluminum is also used in power transmission lines.

Construction and Infrastructure: Iron and steel are the main building materials used in construction and infrastructure, for building bridges, buildings and pipelines.

Medical: Titanium is used in the medical field to make prostheses and surgical tools, and is popular for its biocompatibility and corrosion resistance.

Shaoyi’s Metals Applications

Shaoyi has been playing a leading role in the application of metallic materials in different industries. Our innovations and applications cover the following areas:

Automotive Chassis Stampings: We use high strength steel to manufacture automotive chassis stampings to ensure the structural stability and safety of the vehicle.

CNC Product Manufacturing: Our CNC products cover a wide range of metals including aluminum, copper, and titanium, and are used in a variety of industries for the manufacture of high-precision parts.

Building Materials: Shaoyi provides high quality structural steel for building and infrastructure construction.

Aerospace Components: We manufacture lightweight metal components for the aerospace industry to ensure the performance of airplanes and spacecraft.

Medical Devices: Shaoyi manufactures medical device components, including titanium alloys, to support the needs of the medical industry.

Customer Benefits and Value

Through Shaoyi’s metals applications, customers receive the following benefits and value:

High Quality and Performance: Our metal applications ensure that our customers’ products are of high quality and have excellent performance.

Lightweighting and Energy Efficiency: The use of appropriate metal materials helps to lighten products and improve energy efficiency.

Reliability and Safety: Our material applications help improve product reliability and safety to meet industry standards.

Customized solutions: We offer our customers customized solutions for the application of metallic materials to meet their specific needs.

Future Prospects

Shaoyi remains at the forefront in the world of metallic materials. We are devoted to continuous research and innovation, looking to develop new metal alloys and advanced material handling technologies to meet the evolving market demands. A particular emphasis will be placed on sustainable and eco-friendly applications of metals, as environmental stewardship takes on greater importance.

In the coming years, metallic materials will retain their pivotal role, not only in traditional areas such as automotive manufacturing and construction, but also in burgeoning fields such as renewable energy and electric vehicles. Shaoyi is poised to actively participate in and lead these transitions, offering customers cutting-edge solutions in an ever-competitive market landscape.

In short, Shaoyi has always stood out in the characterization and application of metallic materials. We remain unwavering in our commitment to deliver top-notch, high-performance metal material solutions to meet the needs of a variety of industries. Thank you for your trust and support. We’re eager to shape the future and co-create a brighter tomorrow with you. If you have any questions or needs about our metal application services, please feel free to contact us.