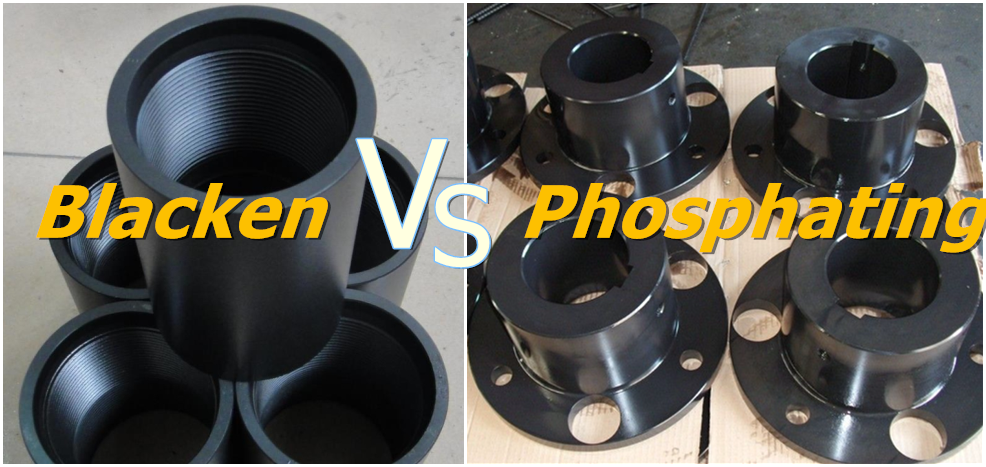

Phosphating vs.Blackening: Decoding Differences with Shao Yi’s Expertise

Introduction:

Phosphating vs. Blackening:In the intricate realm of metal surface treatments, where precision and performance are paramount,two processes often spark curiosity and questions: phosphating and blackening.Shao Yi, a beacon of innovation in automotive metal components, stands at the forefront of these processes. In this extensive blog, we delve into the nuances of phosphating and blackening, decoding their differences, applications, and the expertise Shao Yi brings to the table.

1. Understanding Phosphating:

a. The Phosphating Process:

Phosphating, also known as phosphate conversion coating, involves the application of a phosphate layer to metal surfaces. This chemical conversion process results in the formation of a thin, adherent, and crystalline phosphate coating, typically phosphate or manganese phosphate

b. Key Characteristics of Phosphating:

Phosphating provides excellent corrosion resistance by forming a protective layer on the metal surface.The process enhances the adhesion of subsequent coatings, such as paints or lubricants.Phosphating is widely used as a pre-treatment for components in the automotive industry, offering a robust foundation for further finishing processes.

c. Applications of Phosphating:

Shao Yi leverages phosphating in the manufacturing of automotive components, including chassis supports, shock absorber mounts, and trailer hook parts. The corrosion resistance and improved adhesion provided by phosphating contribute to the longevity and performance of these critical components.

2. Decoding Blackening:

a. The Blackening Process:

Blackening, often referred to as black oxide coating or bluing, is a chemical process that results in the formation of a black oxide layer on the metal surface. This layer enhances the metal’s corrosion resistance while imparting a sleek, black finish.

b. Key Characteristics of Blackening:

Blackening provides an aesthetically pleasing, uniform black finish to metal components.

The process enhances corrosion resistance by forming a controlled layer of black oxide.

Blackening is commonly employed for decorative purposes in addition to functional benefits.

c. Applications of Phosphating:

Shao Yi leverages phosphating in the manufacturing of automotive components, including chassis supports, shock absorber mounts, and trailer hook parts. The corrosion resistance and improved adhesion provided by phosphating contribute to the longevity and performance of these critical components.

2. Decoding Blackening:

a. The Blackening Process:

Blackening, often referred to as black oxide coating or bluing, is a chemical process that results in the formation of a black oxide layer on the metal surface. This layer enhances the metal’s corrosion resistance while imparting a sleek, black finish.

b. Key Characteristics of Blackening:

Blackening provides an aesthetically pleasing, uniform black finish to metal components.

The process enhances corrosion resistance by forming a controlled layer of black oxide.

Blackening is commonly employed for decorative purposes in addition to functional benefits.

c. Applications of Blackening:

Shao Yi utilizes blackening in the production of automotive components where both functional and aesthetic attributes are crucial. Parts such as chassis brackets and frame components benefit from the corrosion resistance and visual appeal achieved through the blackening process.

3. Distinguishing Features: Phosphating vs. Blackening:

a. Color and Appearance:

Phosphating typically results in a light, non-reflective coating, often grey or light in color.

Blackening, as the name suggests, imparts a distinct black finish to the metal surface, enhancing its visual appeal.

b. Corrosion Resistance:

Both phosphating and blackening contribute to corrosion resistance, but the extent may vary. Phosphating provides a durable protective layer against corrosion, while blackening offers a controlled black oxide layer for enhanced resistance.

c. Surface Adhesion:

Phosphating is renowned for its ability to improve the adhesion of subsequent coatings, making it an ideal pre-treatment for paints and lubricants.

Blackening primarily focuses on corrosion resistance and visual aesthetics, with limited impact on surface adhesion compared to phosphating.

d. Applications in Automotive Manufacturing:

Phosphating finds extensive use in the automotive industry as a pre-treatment for components that require enhanced corrosion resistance and improved adhesion.

Blackening is employed in components where a black finish is desired for both functional and decorative purposes, contributing to the overall aesthetics of the vehicle.

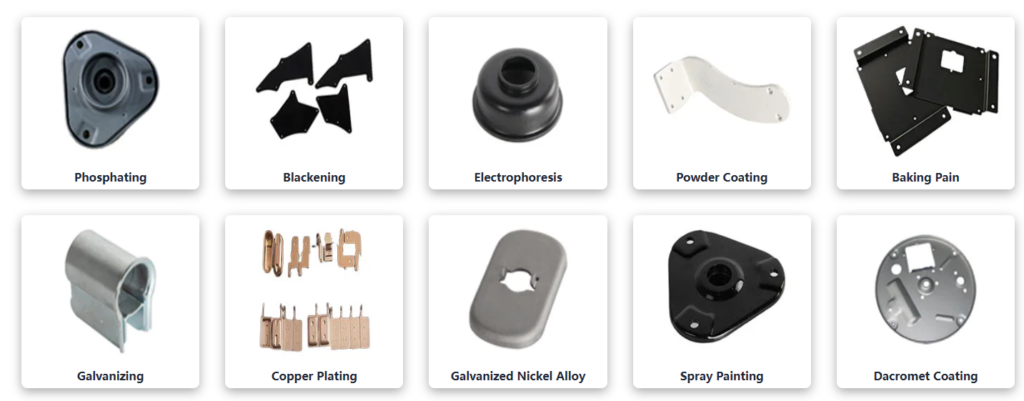

4. Shao Yi’s Expertise in Surface Treatments:

a. Comprehensive Solutions:

Shao Yi’s expertise in surface treatments extends beyond phosphating and blackening. The company offers a comprehensive range of solutions tailored to meet the diverse needs of the automotive industry.

b. Customization for Automotive Components:

Shao Yi understands the critical role that surface treatments play in the performance and longevity of automotive components. The company’s surface treatment processes are customized to meet the specific requirements of each component, ensuring optimal functionality and durability.

c. Quality Assurance:

Shao Yi places a strong emphasis on quality assurance in surface treatments. Rigorous testing and adherence to industry standards guarantee that components undergo reliable and effective surface treatments, meeting or exceeding customer expectations.

5. The Future of Surface Treatments in Automotive Manufacturing:

a. Continuous Innovation:

Shao Yi envisions a future where surface treatments continue to evolve. The company remains committed to continuous innovation, exploring new technologies and processes to enhance the performance, aesthetics, and sustainability of surface treatments in automotive manufacturing.

b. Eco-Friendly Solutions:

The future holds a focus on eco-friendly surface treatment solutions. Shao Yi aims to contribute to sustainable practices by exploring environmentally friendly alternatives and processes in surface treatments.

c. Global Impact

As Shao Yi continues to advance in surface treatments, the company aspires to make a global impact. The expertise developed in phosphating, blackening, and other surface treatment processes positions Shao Yi as a leader in the automotive components industry on a global scale.

Conclusion:

In the labyrinth of surface treatments, where precision meets aesthetics, phosphating and blackening stand out as pivotal processes, each with its unique attributes and applications. Shao Yi’s expertise in these surface treatments reflects a commitment to excellence in automotive manufacturing, ensuring that components not only perform optimally but also exhibit a visual appeal that aligns with the industry’s ever-evolving standards. As we unravel the mysteries of phosphating and blackening, Shao Yi remains at the forefront, shaping the future of surface treatments in the automotive landscape with a blend of innovation, customization, and unwavering quality.

Want to learn how to apply phosphating or blackening technology to your automotive components? Contact Shao Yi’s team for professional consultation and customized solutions.