Shao Yi’s Perspective: Unveiling the Art and Science of Surface Blackening Treatment

Introduction:

In the intricate realm of metal manufacturing, where precision meets innovation, surface treatments play a pivotal role in enhancing both aesthetics and functionality. One such fascinating process is surface blackening treatment, a technique that goes beyond appearances to deliver durability and corrosion resistance. In this comprehensive blog, we delve into the art and science of surface blackening treatment, exploring its applications, methodologies, and the unique perspective that Shao Yi brings to this transformative process.

1. Understanding Surface Blackening Treatment:

a. The Basics:

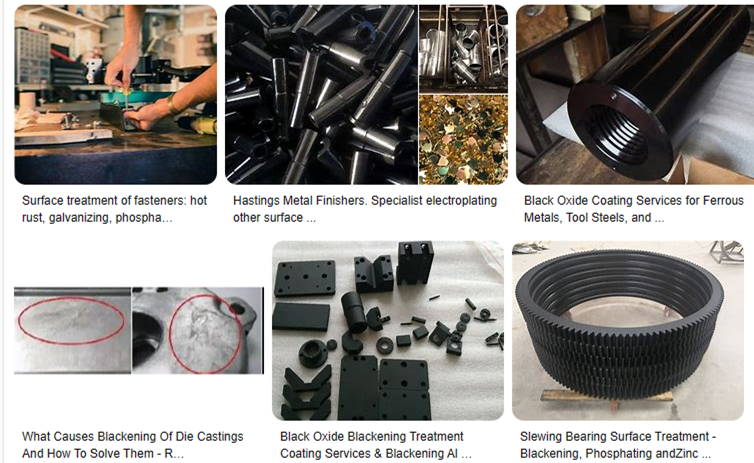

Surface blackening treatment, also known as black oxide coating or blackening, is a chemical process applied to ferrous metals to create a thin layer of black iron oxide on the surface. This layer not only provides a distinctive black appearance but also serves as a protective barrier against corrosion.

b. The Art of Transformation:

Beyond its functional benefits, surface blackening is an art form that transforms the visual aesthetics of metal components. The deep, lustrous black finish adds a touch of sophistication and elegance, making it a popular choice for a wide range of applications.

2. Applications of Surface Blackening:

a. Automotive Components:

Shao Yi, as a leading manufacturer of OEM automotive metal components, extensively employs surface blackening treatment. From chassis supports to brackets, the blackened finish enhances both the visual appeal and durability of these critical components.

b. Industrial and Machinery Parts:

Surface blackening is widely utilized in the industrial and machinery sector. Critical parts that are exposed to harsh environments benefit from the corrosionresistant properties imparted by the black oxide coating, extending the lifespan of machinery.

c. Firearms and Defense Equipment:

In the defense industry, surface blackening is a standard practice for firearms and equipment. Apart from its corrosion resistance, the black finish minimizes glare, reduces light reflection, and provides a nonreflective surface, contributing to tactical advantages.

d. Consumer Goods:

Everyday items, such as tools, fasteners, and decorative pieces, often undergo surface blackening treatment. This not only enhances their durability but also elevates their visual appeal, making them stand out in the market.

3. The Science Behind Surface Blackening:

a. Chemical Reactions:

Surface blackening involves a series of chemical reactions, typically in a controlled environment. The metal is immersed in an alkaline solution containing oxidizing agents, which reacts with the surface to form a layer of black iron oxide.

b. Formation of Magnetite Layer:

The black layer primarily consists of magnetite (Fe3O4), a stable compound that acts as a protective barrier against corrosion. This layer is integral to the durability and longevity of the treated metal.

c. Temperature Control:

Temperature plays a crucial role in the blackening process. Shao Yi’s expertise lies in precise temperature control during the treatment, ensuring uniform black oxide coating and preventing issues such as uneven coloration or excessive scaling.

4. Shao Yi’s Unique Perspective on Surface Blackening:

a. Precision and Consistency:

Shao Yi’s commitment to precision manufacturing extends to surface blackening. Our advanced manufacturing facilities are equipped with stateoftheart systems that ensure precise control over variables such as temperature, immersion time, and chemical composition, resulting in consistent and highquality blackening.

b. Corrosion Resistance:

As a company focused on automotive components, Shao Yi places a paramount emphasis on the corrosion resistance imparted by surface blackening. Our treated components not only meet industry standards but exceed expectations, ensuring the longevity and reliability of the final products.

c. Visual Appeal and Branding:

Shao Yi recognizes the visual appeal of surface blackening as an extension of the brand identity. The distinctive black finish on our components not only communicates a sense of quality and craftsmanship but also contributes to the overall aesthetics of the vehicles our components adorn.

5. Benefits and Considerations of Surface Blackening:

a. Enhanced Corrosion Resistance:

The primary benefit of surface blackening is the enhanced corrosion resistance it provides to metal components. The black oxide layer acts as a barrier against environmental factors, extending the lifespan of treated parts.

b. Improved Lubricity:

Surface blackening contributes to improved lubricity, reducing friction between metal components. This is particularly advantageous in applications where moving parts need to operate smoothly and with minimal wear.

c. Aesthetic Appeal:

The black finish adds a touch of sophistication and elegance to metal components, making them visually appealing. This aesthetic enhancement is a significant consideration, especially in industries where the appearance of components is a key factor.

d. NonReflective Surface:

In applications such as firearms and defense equipment, the nonreflective nature of the black oxide coating provides tactical advantages. The absence of glare and reduced light reflection contribute to improved stealth and concealment.

e. Considerations for Dimensional Changes:

It’s essential to consider that surface blackening may result in slight dimensional changes in the treated components. Shao Yi’s expertise lies in mitigating these changes to ensure that the treated parts maintain precise tolerances and dimensions.

6. Quality Assurance in Surface Blackening:

a. Stringent Testing Protocols:

Shao Yi’s commitment to quality assurance extends to the surface blackening process. Rigorous testing protocols are in place to ensure that treated components meet or exceed industry standards for corrosion resistance, appearance, and functionality.

b. Adherence to Specifications:

Surface blackening at Shao Yi is conducted with meticulous adherence to specifications. Whether it’s automotive industry standards or custom requirements, our processes are tailored to meet the unique needs of each application.

7. Environmental Considerations and Sustainability:

a. Effluent Treatment:

Shao Yi places a strong emphasis on environmental sustainability. Effluent treatment processes are implemented to ensure responsible handling of chemicals used in the blackening process, minimizing environmental impact.

b. Waste Minimization:

Efforts are made to minimize waste generated during surface blackening. Shao Yi invests in technologies and processes that reduce waste, contributing to sustainable practices in metal manufacturing.

Conclusion:

In the intricate dance of science and art that defines surface blackening treatment, Shao Yi stands as a beacon of excellence. Our unique perspective, grounded in precision manufacturing and a commitment to quality, elevates surface blackening beyond a mere process—it becomes a testament to durability, aesthetics, and the relentless pursuit of perfection. As we continue to push the boundaries of innovation, surface blackening remains a key chapter in Shao Yi’s story, contributing to the resilience and visual allure of the automotive components that bear our mark.

FAQs on Shao Yi’s Surface Blackening Treatment

1. What is surface blackening treatment, and how does it differ from other coating processes?

Surface blackening treatment, also known as black oxide coating, is a chemical process applied to ferrous metals to create a thin layer of black iron oxide. Unlike traditional coatings, such as painting or plating, surface blackening forms a protective layer that enhances corrosion resistance while providing a distinctive black finish.

2. What are the primary applications of surface blackening treatment at Shao Yi?

Shao Yi extensively applies surface blackening treatment to automotive components, industrial and machinery parts, firearms, defense equipment, and consumer goods. The treatment enhances both the visual appeal and durability of these components, making them suitable for various applications.

3. How does surface blackening contribute to corrosion resistance?

Surface blackening forms a layer of black iron oxide, primarily magnetite (Fe3O4), on the metal surface. This layer acts as a barrier against corrosion, protecting the metal from environmental factors and extending its lifespan.

4. What is Shao Yi’s unique perspective on surface blackening treatment?

Shao Yi’s unique perspective on surface blackening lies in precision and consistency. Advanced manufacturing facilities enable precise control over variables, including temperature and chemical composition, ensuring consistent and highquality blackening. The company also emphasizes corrosion resistance, visual appeal, and branding.

5. Does surface blackening result in dimensional changes in treated components?

Surface blackening may result in slight dimensional changes in treated components. Shao Yi’s expertise lies in mitigating these changes to ensure that treated parts maintain precise tolerances and dimensions.

6. How does Shao Yi conduct quality assurance for surface blackening treatment?

Shao Yi employs stringent testing protocols to ensure that treated components meet or exceed industry standards. Testing encompasses corrosion resistance, appearance, and functionality, with a focus on adherence to specifications.

7. What environmental considerations and sustainability practices does Shao Yi implement in surface blackening treatment?

Shao Yi places a strong emphasis on environmental sustainability in surface blackening treatment. Effluent treatment processes are implemented to handle chemicals responsibly, and efforts are made to minimize waste generated during the process, contributing to sustainable practices in metal manufacturing.

Contact Shaoyi for more OEM metal parts manufacturing services!